Troubleshooting Broken Cables: 20 Reasons Cables Come Loose Off The Drums

Cables are a crucial part of the garage door counterbalancing system, so when they come loose from the drums or pulleys your door won’t work. Common reasons for thrown cables include; setting the door down on an object, corrosion, broken springs and improper tension.

Springs are under an extreme amount of tension and this force is transferred to the cables and circular spools called drums (torsion springs) or sheaves (extension springs). Broken or loose cables can render heavier garage doors unusable since the force of the springs won’t provide any lifting force. Overhead doors with loose cables are often found stuck closed or hanging halfway in the opening with a tangled mess of cable around the drums.

Garage door repair technicians and homeowners are able to reset or replace the cables, but many fail to diagnose why the cables broken or came loose in the first place. This results in re-occurring cable problems – posing safety risks, financial loss and inconvenience to the business or homeowner.

Table of Contents

What do garage door cables do?

What causes garage door cables to slip off the drums?

What causes garage door cables to break?

Can you open the garage door with a broken or loose cable?

1. Door Set On Object

2. Broken Torsion Spring

3. Broken Extension Spring

4. Jackshaft Opener On Standard Lift Door

5. Excessive Manual Force

6. Corrosion From Damp Environments

7. Wrong Spring Configuration

8. Improper Torsion Spring Tension

9. Wrong Cable Drum Configuration

10. Frayed Cable Assembly

What do garage door cables do?

The purpose of cables is to transfer the lifting force of the torsion springs or extension springs to the bottom brackets of your door. Garage doors are counterbalanced in a system that uses lift cables and sometimes retaining (safety) cables.

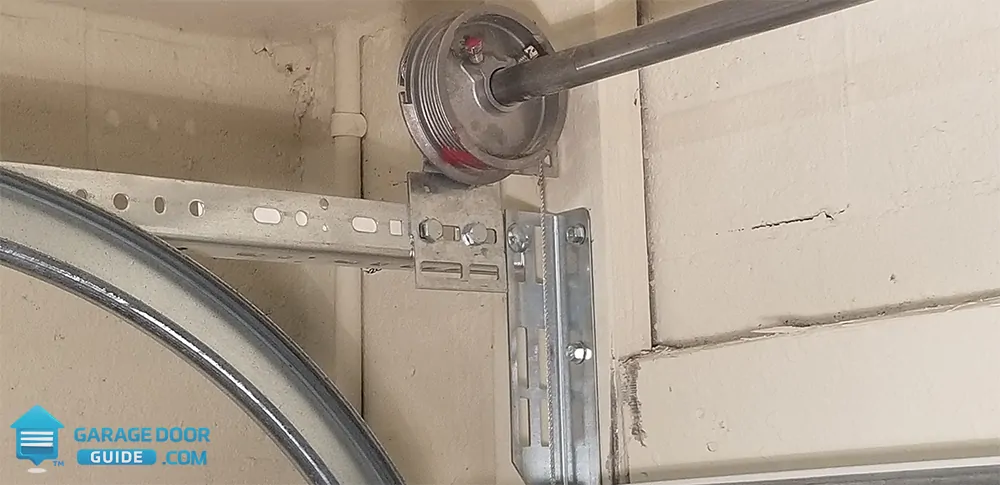

Lift cables wrap around the drums or sheaves and anchor to the bottom fixture brackets on each side of the door. For torsion spring systems cable drums are used and for extension spring systems sheaves are used.

Retaining cables are installed through the hollow interior of extension springs. In the event that your springs break these safety cables prevent the broken pieces from flying off and hitting objects (vehicle) inside the garage. Since torsion springs are anchored to a tube or shaft they don’t need retaining cables.

What causes garage door cables to slip off the drums?

The two main reasons cables come off the drums are slack in the cables or the cables breaking. Loose cables are the enemy of a functioning cable drum assembly. Slack usually comes from user error, broken springs or cable corrosion. Maintaining constant tension throughout the entire opening and closing cycle of your door is crucial to safe and efficient operation.

Resetting or replacing garage door cables is a common repair, but its even more important to figure out the root cause of the problem. Here is a non-exhaustive list of reasons for loose or broken cables.

What causes garage door cables to break?

The most common reasons for broken cables include rubbing against another metal part, corrosion and violent drops in the opening caused by a broken spring. Lift cables are designed to withstand a lot of force – many having breaking strength in excess of 1,000 LBS.

None of that rated breaking strength matters if the cables have been weakened. Cables that constantly rub against another metal object (fraying) or come into heavy contact with water or salt (corrosion) will weaken over time.

In the event your garage door springs break while the door is in the open position, the force of the door dropping quickly could cause cable failure.

Can you open the garage door with a broken or loose cable?

When a cable breaks or slips loose most of the tension is transferred to the opposite side. Opening or closing the door with loose cables can be dangerous. The remaining cable could snap causing the door to crash down to the floor or get stuck halfway in the opening.

Avoid using your garage door opener since the added force needed to lift the door could strip the internal nylon drive gear. If your are considering cutting the cables or disconnecting the opener (red release cord) be sure to install vice grips on both vertical tracks to secure the door in place. This will prevent the door from potentially crashing down to the floor.

The list of reasons for thrown cables is long and varies by the type of counterbalancing system your door uses. Torsion springs and extension spring systems counterbalance the door using different hardware and mechanics. This is by no means an exhaustive list, but it does highlight the more common reasons for loose or broken cables.

Use this list to troubleshoot and diagnose the root cause of your garage door cables breaking and coming loose.

1. Door Set On Object

The number one reason cables slip off the drums is the door being set down on top of an object in the opening. Often times its an object that circumvents the path of the safety eyes that sit 6 inches off the ground. Common objects include the bumper of a vehicle, broom handles, chairs and tools.

An overhead door set down on an object creates an uneven weight distribution and slack in the cables on one side of the door. The slack can cause the cable to jump across the grooves in the drums, causing a tangled mess or worse. Doors that sit crooked in the opening are most often caused by closing the door on top of an obstruction.

2. Broken Torsion Spring

If a spring breaks with the door in the open position it could come crashing down to the floor. It’s best to have two springs installed for this reason. If one spring breaks the second spring can temporarily keep some tension on the cables until repairs can be made. When a (single solution) spring breaks the door doesn’t have a backup. This can cause slack in the cables causing them to slip out of the grooves.

In the process of the door dropping towards the ground a large amount of force is generated. Even torsion cables with a high weight rating can snap during this event. Anyone who has gone fishing or tried to tow a vehicle can understand how slack multiplies breaking force. Thankfully, most garage doors are kept in the closed position the majority of the time so this is a rare occurence.

3. Broken Extension Spring

Unlike torsion springs which mount over the (header) top of the door, extension springs are installed along the horizontal tracks and stretch out. Extension springs are in the relaxed position with the door open and add tension as the door closes using the force of gravity. During an opening cycle these “stretch” springs release tension to assist the door up.

In the event of one of these extension springs breaking the cables usually unwrap or get tangled around the pulley. If this happens with the door in the closed position you will notice slack in the cables and a loose spring hanging down. Hopefully you have “safety” cables installed through the inside of the extension springs to prevent damaged to person or property (vehicles) in the garage.

4. Jackshaft Opener On Standard Lift Door

The Liftmaster 8500 side mount jackshaft opener is the best opener available for a variety of reasons. (You can read all about why i’ll never buy another drawbar opener again).Unfortunately, these openers have one huge drawback (that can be mitigated). Side mount jackshaft openers have a tendency to throw cables off the drums on standard lift track setups – especially commercial grade openers.

Jackshaft openers are best used on doors that have high lift, vertical lift and follow the roof pitch track configurations because a natural downward acting force occurs from gravity. On the other hand, standard lift doors lack this downward force because the track curves horizontally instead of angled.

You can stop jackshaft openers from throwing cables by doing a few key things. First, make sure the horizontally tracks are slightly angled (1-3 inches) from front to back to help create a downward acting force. Then consider installing pusher spring bumpers at the end of the horizontal tracks to eliminate the slack caused by the opener jumping when starting down.

5. Excessive Manual Force

Most door owners choose to have an automatic garage door opener installed for convenience. For those that don’t manual force must be used to open and close the door. That means picking the door up off the ground to the open position and pulling it back down to close it.

A fully opened door rests (flush) between 0 to 3 inches in the opening – meaning the bottom of the lowest garage door section is usually visible with the door considered fully open. If the door is raised too fast or above parallel with the header the cables can slip off the drums. These two reasons explain why most storage facilities use rollup doors vs sectional doors. Renters use excessive force opening and closing the doors securing their units.

6. Corrosion From Damp Environments

Most attached garages in residential settings have a reasonably controlled climate. However, commercial doors are sometimes found on car washes, agricultural buildings and road salt storage facilities. In these instances moisture and chemicals (salt) can weaken metal door components such as the cable fittings.

Corrosion occurs when elements like moisture interact with refined metals. Whenever iron, water and oxygen interact you get rust – which severely weakens the metal into a flaky powder. Usually this is going to happen at the very bottom loop sleeve end of the cable since it is closer to the ground. A severely weakened cable will eventually break, potentially causing damage to the door or anything underneath it.

If this matches your building description you will need to monitor the cables on a monthly basis checking for rust buildup. Consider using a higher quality cable that is zinc-aluminum coated, thicker diameter and has a higher thread construction.

7. Wrong Spring Configuration

Garage doors are counterbalanced by torsion or extension springs. If these springs are not calibrated or installed per manufacturer specifications the door won’t work properly. Springs that are too weak or too hot will cause slack in the cables leading to the cables being thrown off the drums.

Springs that are too strong pose a significant threat to safety and performance. If the springs are too strong the door will rocket up quickly and past the designed maximum opening position. Manufacturers provide engineering reports (especial for commercial doors) that show detailed specifications for springs, drums and other metrics. When installing a heavy commercial overhead door you should always ask for a manufacture specification print out.

8. Improper Torsion Spring Tension

Springs are defined by length, inside diameter, wire gauge and wind direction. If you install torsion or extension springs incorrectly by using the wrong springs or bad installation practice the cables will come unwound. Examples include adding extra winds to springs that you know are too weak or adding excessive weight to an existing door. Another common mistake is mismatching springs when more than one garage door is being installed at the same time.

Having the wrong tension on your torsion springs will cause the cables to slip. Having too much tension (running hot) on your springs can cause momentary slack as the door goes up above the header. Springs that are too weak (dead) will cause the door to drift, unwinding cables from the grooves in the drums. Cables should be under constant tension, similar to that of a violin string.

| Full Turns | Quarter Turns | |

|---|---|---|

| 7ft Door Height | 7 1/2 | 30 |

| 8ft Door Height | 8 1/2 | 34 |

Winding the springs in the wrong direction is known as backwound springs. On a standard lift track setup the springs are wound from bottom to top (6 to 12 o’clock). Many people accidentally backwind springs by adding tension in the wrong direction. Not only does this ruin the spring, but it will also cause cables to slip the drums. The only time torsion springs get wound from top to bottom is on low headroom clearance configurations where the drums are flipped to the outside.

9. Wrong Cable Drum Configuration

Cable drums are designed to accept specific diameters and lengths of cable. They are also compatible with specific track configurations. Most residential doors require standard lift drums (OMI-8 or ATL-8) that are compatible with doors up to 8ft tall and 525 LBS.

Using the wrong size or type of drum with a specific track configuration will cause cables to come off the drums. The grooves on the drums are also sized to accommodate certain cable diameters. Putting too small or too large of cables on certain drums will cause them to slip out of the grooves

| Rating (Pair) | Cable Diameter | Maximum Height | |

|---|---|---|---|

| 8ft Standard Lift | 525 LBS | Up to 1/8" | Up to 8'1" |

| 12ft Standard Lift | 750 LBS | 1/8" - 3/16" | Up to 12'1" |

| 18ft Standard Lift | 1,500 LBS | 3/16" Maximum | Up to 18'1" |

| High Lift 54" | 550 LBS | 3/16" Maximum | Up to 9' 54" High Lift |

| High Lift 120" | 1,000 LBS | 3/16" Maximum | Up to 12' 120" High Lift |

| Vertical Lift 11' | 850 LBS | 3/16" Maximum | Up to 11'1" Door Height |

| Vertical Lift 18' | 1,000 LBS | 3/16" Maximum | Up to 18'11" Door Height |

10. Frayed Cable Assembly

Cables assemblies are commonly composed of 7×7 and 7×19 thread construction, meaning a cable diameter of 1/8 actually has 7 separate smaller cables with 7 or 19 threads. Several smaller cables wind together to make a thicker cable.

Fraying is caused by the cable assembly rubbing against an object on your door over a long period of time. When the outer threads of cable construction start fraying, added stress is transferred to the remaining threads. Over time inner threads also weaken until eventually the entire cable diameter snaps in half.

Cables can rub against the edge of the door, bottom brackets, track or bearing plates. it is important to inspect both the cable and door for signs of wear and friction. Cables usually fray and snap closer to the bottom near the sleeve end. For some applications like box truck doors it is important to have a spool inside the cable loop to prevent fraying.

11. Wrong Cable Strength Rating

Cable diameter is the main factor in determining cable strength – thicker cable equals higher minimum breaking strength. The type of material (Galvanized vs Stainless Steel) and thread construction (7×7 vs 7×19) also influence the strength of the cable.

Using a small diameter cable on a heavy door can cause the cable assembly to fail, but all residential doors are safe using 1/8″ diameter cable. Both the drums and lift cables are rated for at least 500 LBS.

| Cable Diameter | 3/32" | 1/8" | 3/16" | 1/4" |

|---|---|---|---|---|

| Galvanized (GAC) 7x7 Contruction | 920 LBS | 1,700 LBS | 3,700 LBS | 6,100 LBS |

| Galvanized(GAC) 7x19 Construction | 1,050 LBS | 2,000 LBS | 4,200 LBS | 7,000 LBS |

| Stainless (SSAC) 7x7 Construction | 920 LBS | 1,700 LBS | 3,700 LBS | 6,100 LBS |

| Stainless (SSAC) 7x19 Construction | 920LBS | 1,760 LBS | 4,200 LBS | 6,400 LBS |

12. Loose Set Screws

Each cable drum has two set screws (Painted Red) that fix the drums in place on the torsion tube or shaft. These set screws are easily over or under tightened. When installing drums its recommended that you tighten the set screws as tight as you can by hand. Then using a wrench, tighten another 1/2 turn to 3/4 turn.

Not tightening the set screws down strong enough increases the chances of them slipping loose. This can cause the drum to spin loose from its fixed position on the shaft. Oppositely, over-tightening the set screws can cause the torsion tube to crimp or crack. This also causes the set screws to slip loose from the shaft.

13. Loose Or Uneven Installation

Loose and uneven tension during initial installation will cause problems quickly. When you set the cables drums be sure to check for relatively even cable tension on each side of the door. Installing one cable drum tighter than the other will cause the opposite side to unwrap.

The same can be said about installing a door on uneven surfaces. Sometimes driveways are sloped and require a universal aluminum retainer to fasten to the bottom of the garage door. If this isn’t done one side of the door will hit the concrete first causing slack in the cables on that side.

The easiest way to tell if your bottom section is sitting level is to turn out the lights in the garage and close the door. If you can see daylight under the bottom seal on one side of the door its possible your door is unlevel. You can also check the bottom seal to see check for excessive wear or flattening on one side or the other.

14. Door Frozen to Floor

If you leave in a warm climate where temperatures rarely get near freezing this won’t apply. For the rest of us, freezing sub-zero temperatures are a major concern. Garage doors that have frozen to the ground from snow and ice buildup are prone to a variety of damage.

In addition to the nylon gear inside your opener stripping, cables are also prone to damage. When you run your opener with the door frozen to the ground, the door can suddenly free up causing a violent jump off the ground. This quick bolt higher results in the cables slacking up and coming loose from the drums.

15. Worn Out Roller Wheels

Garage doors should have ball-bearing rollers (10-ball or 13-ball) installed for smooth and quiet operation. Even premium rollers wear down over time (10,000-20,000 cycles) so it is important to periodically check for wear and damage. The bottom and top rollers tend to have the most problems.

The bottom rollers are your main concern since they are closest to the ground. They wear out the quickest due to frequent contact with dirt, debris and moisture. If the bearing and casing aren’t replaced the wheel can eventually separate from the stem and fall out of the track.

A roller that has fallen out of the track will cause one side of the door to sag, creating an unevenly balanced door. As you continue to run the door up and down the chances of the cables being thrown off the drums increases.

16. Bent Door Sections

Garage door sections are made out of rolled steel in thicknesses around 25-gauge. If the panels become severely bent or creased they should be replaced immediately. Garage doors are relatively thin, relying on stiles and struts for reinforcement.

Bending and creasing the walls of a soda can results in the can eventually breaking completely. The same holds true for garage door sections that have been creased . You can try to reinforce the door with struts or punch angle, but eventually the section will break in half.

Bent panels are a safety hazard and should be closely monitored. Bottom sections are most often damaged since car bumpers and other items in the garage make contact frequently. The bottom bracket fixture are anchored to the corners of the bottom section, so if the bottom panel is weakened the entire door is at risk. A bent or creased bottom panel on your garage door can cause cables to slip off the drums.

17. Defective Cable Assembly

Most cables come pre-made from major hardware suppliers as a cable assembly. Cables are sized, crimped and soldered with precision by machines. Garage door technicians can buy these assemblies wholesale with the assurance of consistent quality. However, some cables might need to be made by the technician by choice or out of necessity. Hand made cables work fine as the person who makes them knows what they are doing.

Over and under crimping cables are major problem to watch out for when making cables. Much like a sinker on a fishing line, the right amount of pressure is necessary.

- Over-crimping will eventually cause the sleeve or stop to crack and can also cause a hidden cut in the cable. Over-crimping is hard to detect as the cable will usually last for a while before eventually failing.

- Under-crimping is a problem that occurs when the sleeve or stop isn’t secured tight enough. Failing to crimp the sleeve or stop down enough can result in slipping and is immediately noticeable during door operation.

- Damage from storage or shipment is also something to look out for. When cables are bought in bulk they are shipped in boxes of 100 or more at a time. If a fork truck or pallet jack smashes or cuts the cable assembly it can cause the cable to weaken and fail.

- Wrong size stops, sleeve or spools on a specific cable diameter is common. When making cables you must match the cable diameter to the appropriate sleeve, stop and spool. If you cable is 1/8″ diameter you should also use 1/8″ sleeves and stops. Using too large of a sleeve or stop forces you to over-crimp.

18. Unlevel or Bent Track

The vertical tracks in your overhead garage door system should be level, flush and plumb. Tracks that were installed unlevel or have shifted can cause your door to bind and pinch during operation. You will need to inspect your vertical track jamb brackets to make sure they aren’t bent or coming loose from the door jamb. If you have backed into the door its possible that your rails have bent enough to prevent smooth door operation.

Unlevel or bent track can cause pinching and catching during operation. Lift cables need consistent smooth tension at all times. Rough operation can cause the cables to pop out of the grooves on the drum.

The horizontal tracks hanging overhead should also be flush and plumb – they do not need to be level. In fact, having a slight pitch helps the door (especially jackshaft openers) down into the opening. The back end of the horizontal tracks can be slightly higher than the front (angled downward).

Horizontal tracks should have even spacing from front to back. Measure the space between each side (front and back) to make sure the spacing is equal. Angling the tracks too far out can cause rollers to fall out of the hinge carriers. Angling too far in can cause the roller to grind against the hinge and track channels.

19. Broken Brackets Or Drums

If your garage door is extremely old its likely that some of the parts will begin to fail. Parts like drums and bottom brackets are under the most tension for the longest amount of time so they tend to fail first.

Drums are made of cast iron and over time the grooves, set screws and stop anchor will wear out. Cast iron can also crack from being dropped or from blunt force. A cracked drum will eventually break in half spilling whatever cable is wrapped around it.

Residential bottom bracket fixtures are made from 13 gauge steel. The side cable attachment flange is extremely durable, but if the door has a sudden drop it can shear off. Using a residential grade on a heavy wood door or commercial door can cause the flange to fail much more quickly.

20. Poor Maintenance Or Installation

Overhead doors that have been poorly installed and maintained wear out fast. Does your door shake, grind, catch or pop during operation? If symptoms like these go unchecked the critical parts of the door will fail much faster. Loud noises and unnatural door action is a sign of a much larger problem developing.

Poorly installed and maintained garage doors wear out fast causing critical components like cables to slip or break. Saving money on the initial installation and then neglecting the door results in higher repair costs in the future.

Seasonal maintenance is required to extend the longevity of your door. Cold temperatures and moisture are especially hard on garage doors so all metal moving parts should be lubricated before and after the winter season. Hinges, sheaves, springs, rollers, cables and brackets should be checked for excessive rust buildup and wear annually.

A garage door balance test should also be completed a few times per year to ensure torsion springs are properly calibrated. When the door is raised halfway in the opening it should stay put. If it drifts lower the spring tension should be increased and if it pulls higher the springs are running too hot so tension should be decreased.

Doors should be installed level, flush, plumb and true to ensure smooth operation and longevity. Avoid hiring shady installers that don’t specialize in garage doors and lack a proven track record. Saving a few dollars on your initial installation could cost you a few years down the road when repairs start piling on. Reputation can easily be tracked through Google Reviews and looking at their website.

Have you experienced anything that didn’t get listed? Send us an email with an explanation along with a picture of the problem and we will add it.